- B1 FR Aluminum

Composite Panel - A2 FR Aluminum

Composite Panel - Aluminum Corrugated

Composite Panel - Aluminum Profiled Core

Composite Panel

-

HyGROW® B1 FR is a traditional fire proof materials used for multipurpose decoration.

Composed with optional fire-retardant as core material,Composed with two sheets of aluminum alloy

3000 or 5000 series in large variety of colors such as PVDF solid/metallic colors,anodized

finish,or decorative film laminated. HyGROW® B1 FR meets the fireproof standard, low

weight,high rigidity, impact-resistance, perfect flatness, excellent weatherproof, can easy to be

folded and bent, fully maintaining all of the building’s design.

- Aluminum

- Non-combustible Core

- Aluminum

- Non-combustible Core

- Smooth Surface

- High Rigidity

- Sound Insulation

- Long Life

- High Flexible

- Easy To Process

- Recyclable

B1 FR Aluminum

Composite Panel

-

HyGROW® COMPOSITES METAL COMPOSITE MATERIALS

METAL FACADE SOLUTIONS

- STRUCTURE

- FEATURE

- B1 FR PANEL SPECIFICATIONS & DIMENSIONING

| Thickness | Width | Panel Length | Aluminum Thickness |

| 3-6mm | 1000-2000mm | up to 5800mm | 0.3-0.5mm |

| Recommended |

| 4.6mm | 1220, 1250, 1500 | 2440, 3050, 4050mm |

- DATA SHEET

| Panel Thickness | Standards | Unit | 4mm | 6mm |

| Aluminum Thickness | mm | 0.5/0.5 | 0.5/0.5 |

| Weight | Kg/m2 | 7.0 | 9.5 |

| Technical Properties |

| Section Modulus | DIN 53293 | cm3/m | 1.25 | 1.75 |

| Rigidity | DIN 53293 | kNcm3/m | 2400 | 2400 |

| Alloy of Aluminum Layers | EN 573-3 | 3003 |

| Alloy of Aluminum Layers | EN 515 | 5005 |

| Modulus of Elasticity | EN 1999-1 | N/mm2 | 70000 |

| Tensile Strength of Aluminum | EN 485-2 | N/mm2 | Rm≥130 |

| Elongation | EN 485-2 | % | A50>5 |

| Linear Thermal Expansion | EN 1999 1-1 | 2.0mm/m(100.C temperature difference) |

| CORE | FR Core |

| Thermal Properties |

| Thermal Resistance | DIN 52612 | m2K/W | 0.006 | 0.009 |

| Temperature | ℃ | -50 to +80 |

-

HyGROW® non-combustible A2 is materials used for.

Composed with mineral-filled polymer fire retardant as core material,Composed with two sheets of

aluminum alloy 3000 or 5000 series in large variety of colors such as PVDF solid/metallic

colors,anodized finish,or decorative film laminated.

HyGROW® A2 FR made with this technology have achieved world’s highest reaction to fire

assistant standard “Class A2-s1,d0” when tested in accordance to European standard EN 13501-1,USA

standard NFPA285 and AUS/NZ standard ISO5660.

HyGROW® A2 FR meets the strictest fire regulation,non-combustible,low weight,high

rigidity,impact-resistance,perfect flatness,excellent weatherproof,can easy to be folded and

bent,fully maintaining all of the building’s design.

- Aluminum

- Non-combustible

- Aluminum

- Non-combustible Core

- Smooth Surface

- High Rigidity

- Sound Insulation

- Long Life

- High Flexible

- Easy To Process

- Recyclable

A2 FR Aluminum

Composite Panel

-

HyGROW® COMPOSITES METAL COMPOSITE MATERIALS

METAL FACADE SOLUTIONS

- STRUCTURE

- FEATURE

- A2 FR PANEL SPECIFICATIONS & DIMENSIONING

| Thickness | Width | Panel Length | Aluminum Thickness |

| 2-4mm | 1000-1600mm | up to 5800mm | 0.3-0.5mm |

| Recommended |

| 1220, 1500mm | 2440, 3050, 4050mm |

- DATA SHEET

| Panel Thickness | Standards | Unit | 4mm | 6mm |

| Aluminum Thickness | mm | 0.4/0.4 | 0.4/0.4 |

| Weight | Kg/m2 | 6.5 | 8 |

| Technical Properties |

| Section Modulus | DIN 53293 | cm3/m | 1.75 | 1.75 |

| Rigidity | DIN 53293 | kNcm3/m | 2400 | 2400 |

| Alloy of Aluminum Layers | EN 573-3 | 3003 |

| Alloy of Aluminum Layers | EN 515 | 5005 |

| Modulus of Elasticity | EN 1999-1 | N/mm2 | 70000 |

| Tensile Strength of Aluminum | EN 485-2 | N/mm2 | Rm≥130 |

| Elongation | EN 485-2 | % | A50>5 |

| Linear Thermal Expansion | EN 1999 1-1 | 2.0mm/m(100.C temperature difference) |

| Peel strength | N | 7 |

| CORE | Mineral-filled Core |

| Thermal Properties |

| Thermal Resistance | DIN 52612 | m2K/W | 0.002 | 0.002 |

| Thermal conductivity | DIN 52612 | W/mk | 1.99 | 1.97 |

| Heat Transition Coefficient | DIN 52612 | W/m2k | 5.83 | 5.8 |

| Temperature | ℃ | -50 to +80 |

-

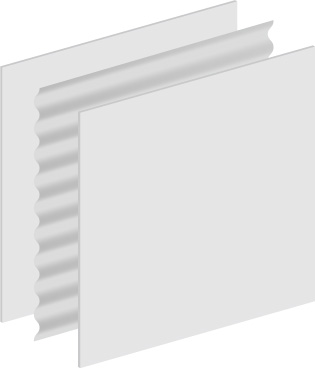

Aluminum corrugated composite panel composed with aluminum corrugated core and one or two layers of

aluminum alloy 3000 or 5000 series in large variety of colors such as PVDF solid/metallic

colors,anodized finish,or decorative film laminated.

The aluminum corrugated core is made of pre-oxidized aluminum alloy sheet, which is usually in the

form of water ripple or trapezoid in order to increase the bonding area between the core material

and the layers of aluminum. Can improve the bonding strength, with a flat tensile strength of 2Mpa.

It is an excellent material for large-scale interior ceiling project and can be used as hook-up

installation system and short vertical edges triangular keel clamping system.

- Aluminum

- Aluminum Corrugated

- Aluminum

- All Metal Material

- Corrugated Core

- Smooth Surface

- High Rigidity

- Sound Insulation

- High Flexible

- Easy To Process

- Recyclable

Aluminum Corrugated

Composite Panel

-

HyGROW® COMPOSITES METAL COMPOSITE MATERIALS

METAL FACADE SOLUTIONS

- STRUCTURE

- FEATURE

- CORRUGATED SPECIFICATIONS & DIMENSIONING

| Thickness | Width | Panel Length | Aluminum Thickness |

| 3-10mm | 1000-1550mm | up to 5700mm | 0.4-1.0mm |

| Recommended |

| 4, 6mm | 1250, 1500mm | 2440, 3050, 4050mm |

- DATA SHEET

| Items | ASTM | Unit | 10mm | 15mm | 20mm |

| Theoretical Unit Weight | kg/m2 | 5.4 | 5.6 | 5.75 |

| Tensile Strength | E8 | N/mm2 | 806 | 598 | 455 |

| Endurance | E8 | N/mm2 | 531 | 405 | 279 |

| Elongation | E8 | % | 1.2 | 1.4 | 1.7 |

| Flexural Rigidity | C393 | *106N.mm2 | 8.05 | 15.4 | 38.44 |

| Coefficient of Linear Expansion | D696 | 0.24 | 0.24 | 0.24 |

| Thermal Conductivity | D976 | *10-6N/℃ | 0.25 | 0.19 | 0.15 |

| Heat Deflection Temperature | D648 | ℃ | 200 | 200 | 200 |

| Cohesion Value | C297 | N/mm2 | 12 | 12 | 12 |

| Flatness | Maximum deviation: 1mm/M |

| Flame Retardance | Non-flammable, comply with fire protection standards |

| Flame Retardance | Depending on installation angle, from 0 to 3dB |

-

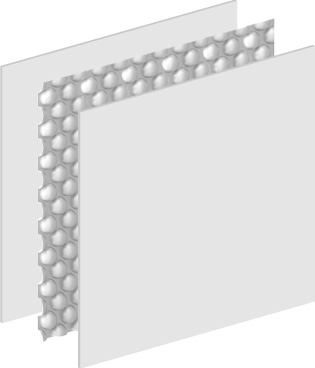

The aluminum profiled core composite panel is continuously compounded under high temperature and

high pressure, which is the same products as the traditional aluminum composite panel (ACP) but new

performance of non combustible. Excellent surface flatness and painting can provide excellent

weather resistance and pollution resistance effect and can be used for building exterior wall with

high fire resistance requirements.

- Aluminum

- Aluminum Profiled Core

- Aluminum

- All Metal Material

- Non-combustible

- Flat surface

- High Rigidity

- Light Weight

- High Flexible

- Easy To Process

- Recyclable

Aluminum Profiled Core

Composite Panel

-

HyGROW® COMPOSITES METAL COMPOSITE MATERIALS

METAL FACADE SOLUTIONS

- STRUCTURE

- FEATURE

-

HyGROW® COMPOSITES METAL COMPOSITE MATERIALS

METAL FACADE SOLUTIONS

- ALUMINUM PROFILED CORE SPECIFICATIONS & DIMENSIONING

| Thickness | Width | Panel Length | Aluminum Thickness |

| 3, 4, 6mm | 1000-1250mm | up to 5700mm | 0.5-0.7mm |

| Recommended |

| 1250mm | 2500, 3200, 4000mm |

- SURFACE & COATING PERFORMANCE