- Thermoplastic PP Honeycomb

Composite Panel

Thermoplastic PP Honeycomb Composite Panel

-

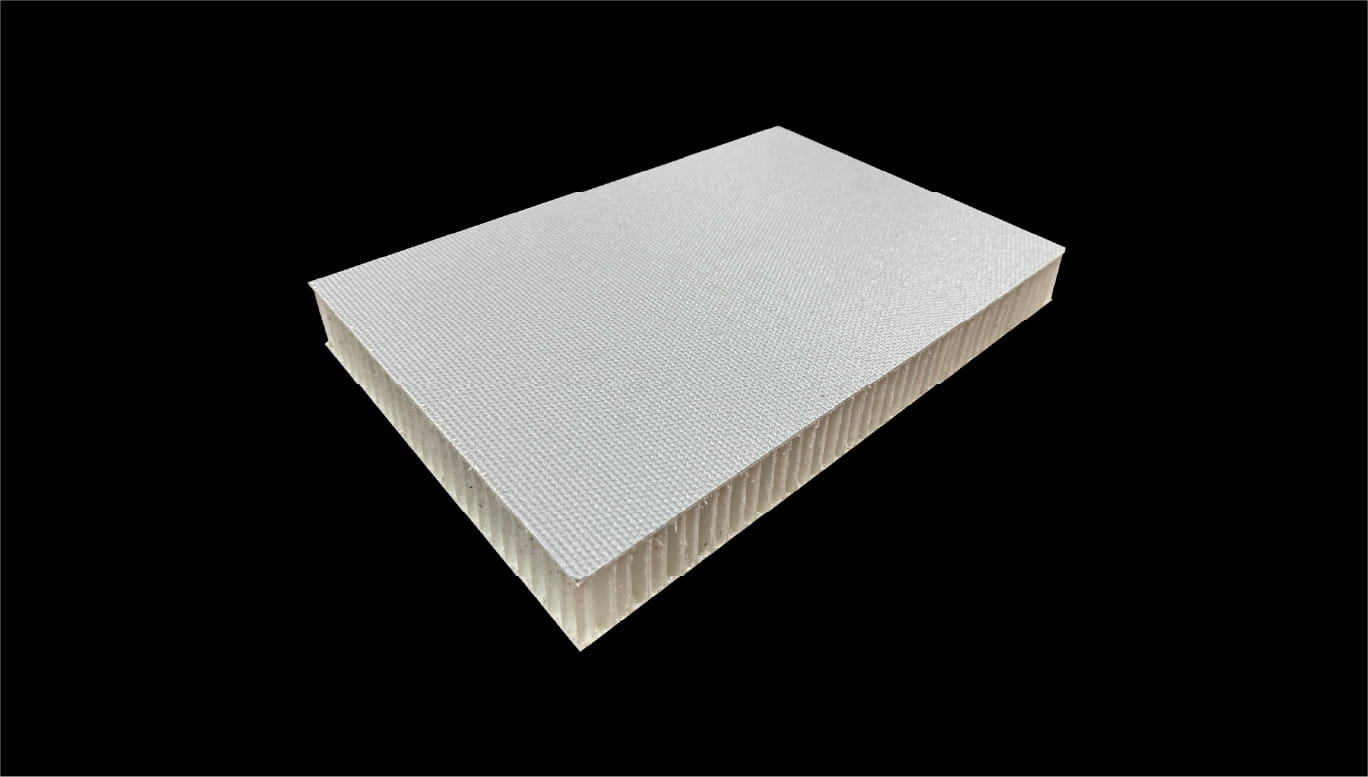

FRP (Fiberglass Reinforced Plastics) honeycomb composite panel is a light and strong

sandwich

panel. It is the composite glass ber on the surface of PP honeycomb core, combined

with the

original special structure of PP core material, so that the glass ber reinforced

honeycomb

board products have excellent performance in physical and chemical properties.

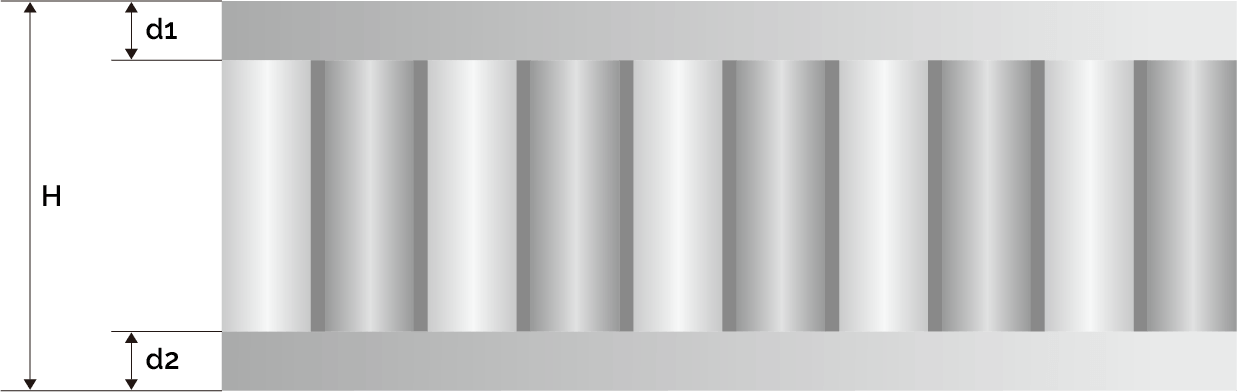

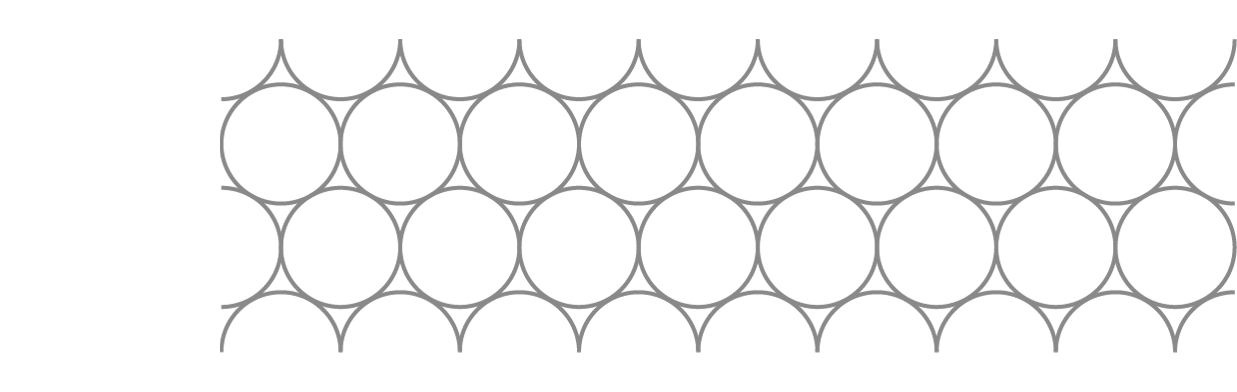

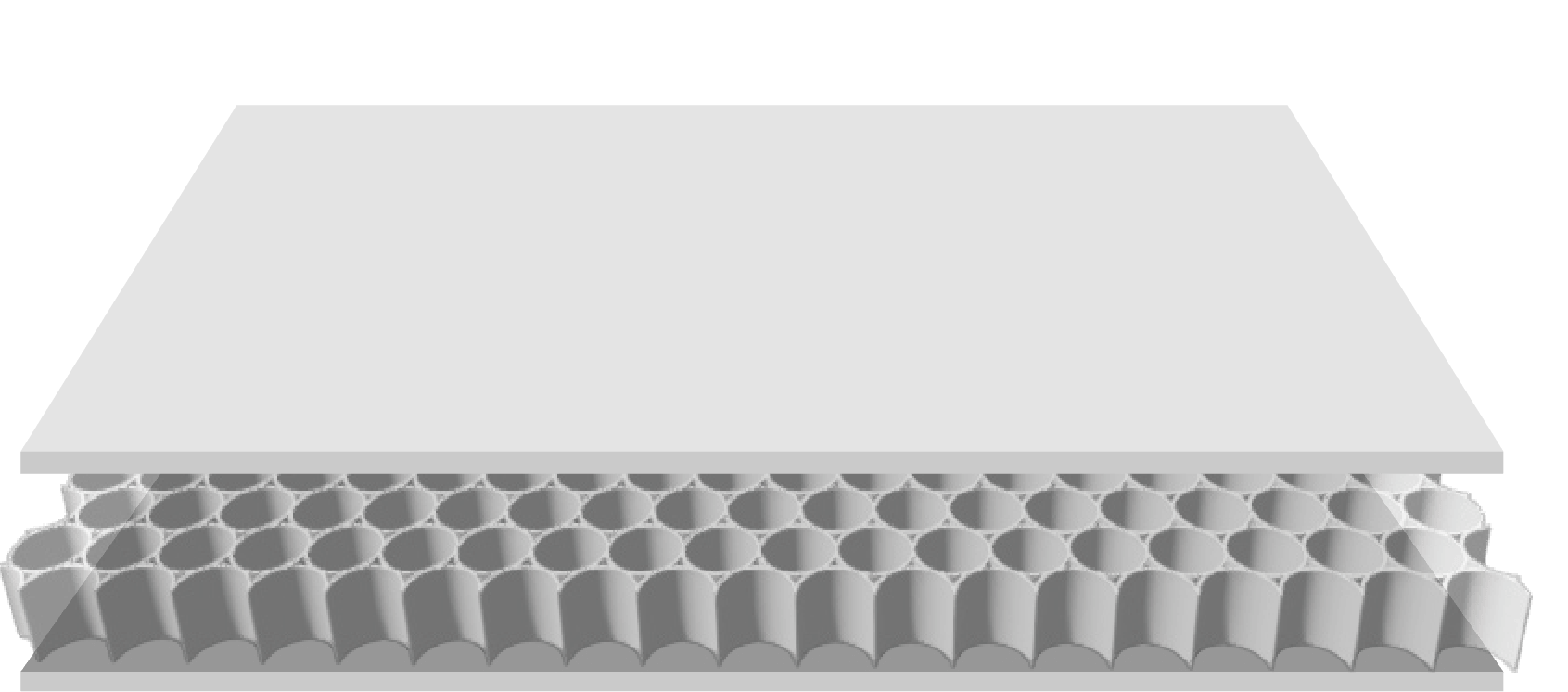

- STRUCTURE

The berglass honeycomb panel is a typical sandwich structure, the upper and lower skins are reinforced sheets mixed with glass ber and resin,and the core material is honeycomb-shaped plastic (usually polypropylene material). The core and berglass skin are usually bonded together using adhesives (thermoset FRP) or thermal bonding (thermoplastic FRP).

- Non-Slip, anti-UV, Fireproof, Film, Coloring

- Polypropylene Honeycomb Core Density

- Non-Slip, anti-UV, Fireproof, Film, Coloring

- ADVANTAGES

-

Light weight

Because of the special honeycomb structure, the density is relatively small and the weight is very light. Using glass fiber honeycomb panel material to manufacture the body, the light and high strength panel can effectively reduce the dead weight of the transport vehicle, improve the speed and load ratio of the transport vehicle.

-

High strength

Strong impact resistance, can absorb the external force, and reduce the damage caused by impact, collision, etc.

-

Waterproof

The difference with wood board is that this material is well sealed, impermeable and watertight, and does not absorb water even if the surface is damaged.

-

Strong resistance to chemical erosion

Because of the characteristics of the raw material, it can be used in the environment with high water content and strong corrosion for a long time.

-

Good sound insulation performance

It can effectively reduce and block the transmission of sound; it can be used as the basic material for sound insulation equipment of transportation vehicles with high noise, such as yachts, cars, motor cars, and the use of decoration materials in noisy places.

-

Easy to assemble

Assembly is very convenient, low cost, can be assembled with screws, hollow rivets, can also be bonded or hot-melt welding.

-

Strong temperature tolerance

the board is a fiberglass reinforced thermoplastic material with a wide range of temperatures from -40℃ to +80℃

-

Workability is wide

The surface of bare board can be painted, anti-skid and other treatments to meet the special requirements of customers; it can be compounded with different plates (such as wood grain board, aluminum plate, stainless steel plate, marble plate, rubber plate, etc.).

TRANSPORT VEHICLE CONSTRUCTION

ANTI-SLIP SCAFFOLDING PANELS

Anti-slip: Only a large friction force can ensure that the construction personnel can walk stably on the platform.

Lightweight: Although the scaffolding is too heavy and stable, it is obviously inconvenient for the construction personnel to operate flexibly.

The materials of traditional non-slip scaffolding boards are mostly wood, bamboo, or metal materials (such as galvanized steel,stainless steel.aluminum plates, etc.,.These maternals are prone to damp rot or rust, or the surface becomes smooth after long-term use. These problems are perfectly solved by Thermoplastic PP Honeycomb Composite Panel.

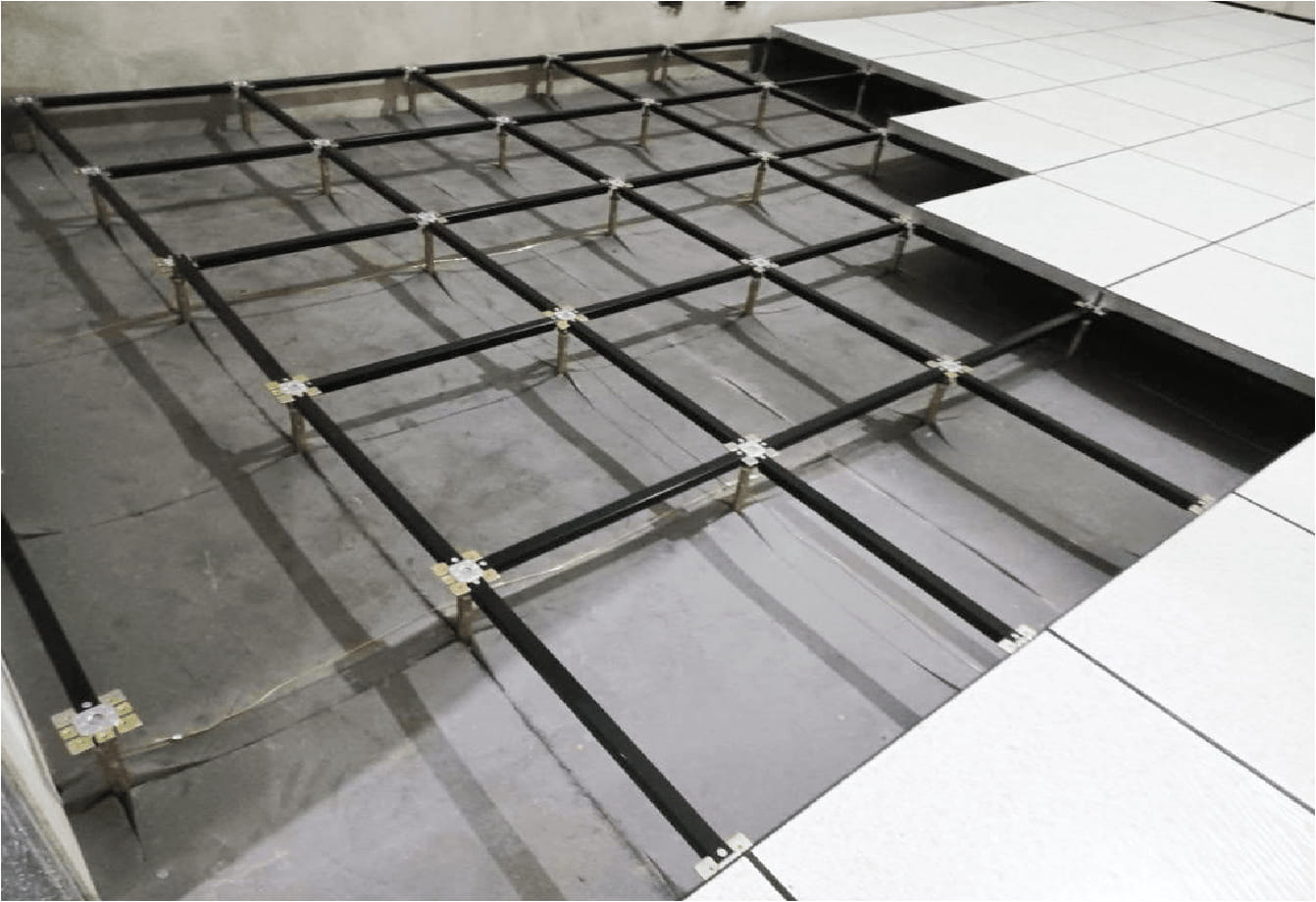

- ANTI-STATIC FLOORING PANELS

Thermoplastic PP Honeycomb Composite Panels are also widely used as laboratory flooring panels, server machine room flooring panels, and all kinds of clean room flooring panels.

INTERIOR CONSTRUCTION

Whether for cleanrooms, partitions, light-weight containers, cabins for machine tools,

wind

tunnels, lifting platforms, lifts, etc., Thermoplastic PP Honeycomb Composite Panels are

the ideal

material for industrial applications.

For example, using large-format, curtain wall Thermoplastic PP Honeycomb Composite Panels,

it is

possible to create an individual interior design in stairways and public areas, fast

building

systems in hat-profile construction can be implemented, or ground areas can be fitted with

assembly

systems for control rooms, navigating bridges and platforms. The honeycomb panels are also

excellently suited as a carrier material for HPL, veneers, foils or paint. Simple

processing using

commercially available tools on site and the possibility of a flexible adaptation of the

modular

dimension and fixation method offer the construction workers the greatest possible

comfort.

Fire Resistant

| TECHNICAL PROPERTIES | UNITS | 20mm | 25mm | 30mm |

|---|---|---|---|---|

| Panel Thickness | From 9mm to 75 mm | |||

| Tolerance of Panel Thickness | mm | ±0.5mm | ||

| FRP Thickness | mm | ≤1mm | ||

| Panel Weight | kg/m2 | 4.5 | 5 | 5.5 |

| Panel Width | From 1000mm to 3200mm | |||

| Compressive Strength | MPa | 1.8 | 1.89 | 1.82 |

| Compression Modulus | MPa | 38.3 | 38.3 | 37.8 |

| Maximum Load | N | 10121 | 10480 | 10239 |

| Damage Load | N | 1722 | 2005 | 2568 |

| Specific Stiffness | N.m/kg | 1.8 | 2.6 | 3.8 |

| Bending Stiffness | N/mm | ≥105 | ≥120 | ≥135 |

| Tensile Strength | MPa | ≥280 | ||

| Flat Tensile Strength | MPa | ≥2 | ||

| Moisture Content | % | 0.2 |

PROCESSING

-

CORNER POST

-

SCREWABLE

-

PAINTABLE

-

FORMABLE

-

CAN BE CUT

-

PENETRABLE

-

STICKABLE

-

WORKABLE

-

CAN BE ADDED

-

PLIABLE