- Aluminium Honeycomb

Core Composite Panel

Aluminium Honeycomb

Core Composite Panel

-

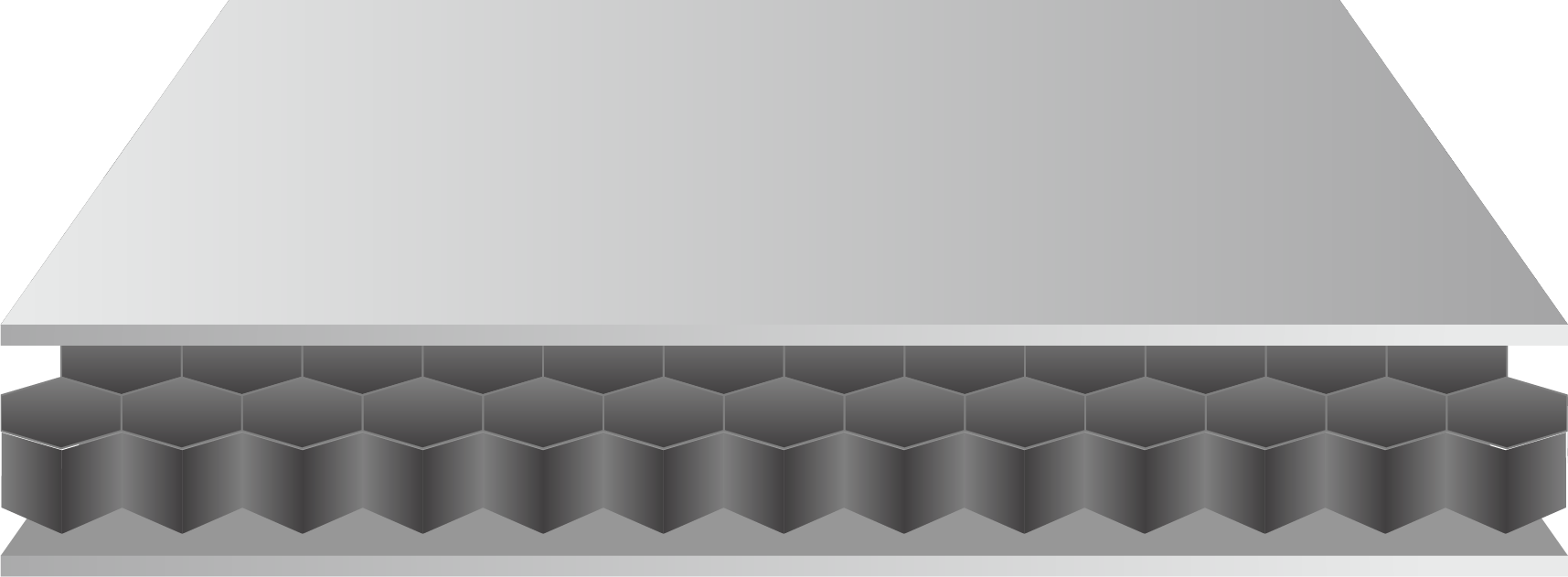

It is an innovative aluminium composite panel consisting of two aluminium cover

sheets and a

honeycomb core of aluminium.

HyGROW Aluminium Honeycomb Core Composite Panel is also a composite material that can be used for a wide variety of applications from the transport industry to architecture, and has fantastic properties such as extraordinary flatness, a large variety of colours, and high formability.

The product’s aluminium honeycomb core gives the composite panel a high rigidity and an extremely low weight. HyGROW Aluminium Honeycomb Core Composite Panel therefore has a definite advantage when it comes to projects with high demands on material stiffness – such as façade cladding or roofing where it will be exposed to an extremely high wind load, or for large self-supporting roofs.

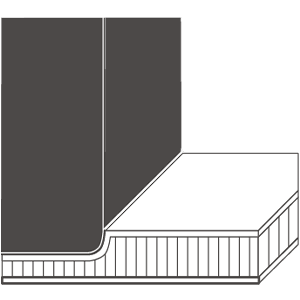

- STRUCTURE

- Cover sheets with lacquering

- Honeycomb

- Cover sheets with lacquering

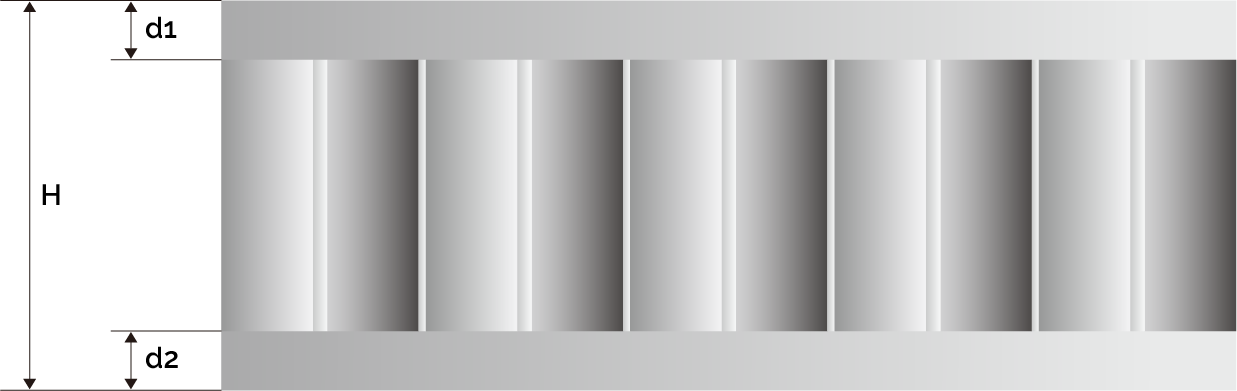

H:total thickness(4-50mm)

L:length(2000-9600mm)

d1: thickness of AI cover sheet (front side 0.3-1.5mm)

d2: thickness of AI cover sheet (rear side 0.3-1.5mm)

- FEATURE

- Anti-UV

- Smooth Surface

- High Rigidity

- Light Weight

- Sound Insulation

- High Flexible

- Easy To Process

- Weatherability

ARCHITECTURE

ARCHITECTURE

RAIL AND TRANSPORT VEHICLE CONSTRUCTION

Today’s strict economic and ecological conditions demand the implementation of sustainable structural materials in the field of transport that are lightweight, stable and fully recyclable.

Fire Resistant

| BUILDING | UNI EN 1350 1-1 |

A1 Classification,non-combustible Class Certification Nr.IN-01746/2017-OC-E |

ALUMINIUM HONEYCOMB A1-Incombustible |

| BUILDING |

NF P92-501-1995 NF EN ISO 171 |

M0 Classification,non-combustible Class Certification RA21-0114 |

ALUMINUM HONEYCOMB M0-Incombustible |

|

Transport Industry |

MOD. B. Certifi cation Nr.: MED- 147 (IG-293-2013) REV.2 2017CS011592 MOD. D. Certifi cation Nr.: MED- 154 (IG-178-2014) REV.13 |

ALUMINIUM HONEYCOMB aluminium honeycomb complying with the MED directive for the application in ships registered or applied in the European Union. Item N. MED/3.13, IMO 2010 FTP Code, Annex 1 |

|

MOD. B. USCG N. approval Nr.: 164.109/EC0407 MOD. D. N. approval.: 164.109/EC0407/MED000154 (for MED/3.13) |

ALUMINIUM HONEYCOMB |

-

Rigidity compared with thickness and weight

-

Characteristic peel strength

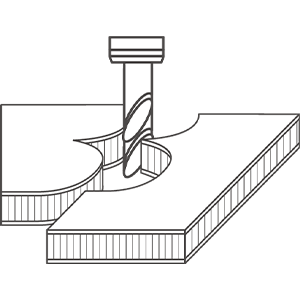

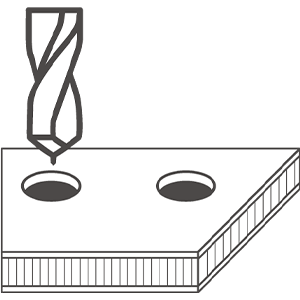

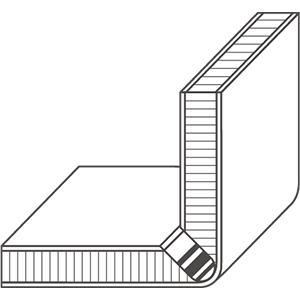

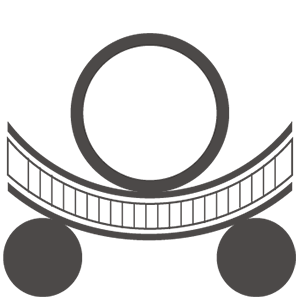

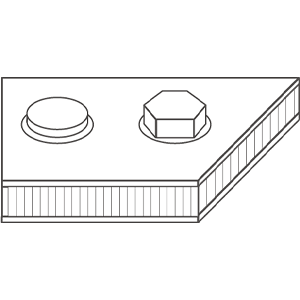

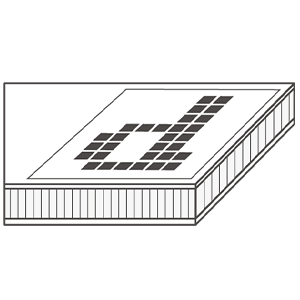

PROCESSING

-

CUTTING

-

MILLING

-

DRILLING

-

FOLDING

-

BENDING

-

PRESS FORMING

-

JOINTING, FIXING

-

EDGE COVERING

-

LAMINATING

-

LACQUERING, SPRAYING

-

PRINTING

-

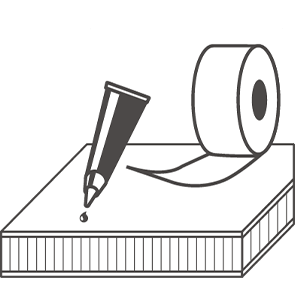

GLUEING

APPLICATION EXAMPLES

INTERESTING DETAILS

-

ENVIRONMENT/ RECYCLING / QUALITY

During the life cycle of HyGROW Aluminium Honeycomb Core Composite Panel, no substances containing CFC are set free at any time. HyGROW Aluminium Honeycomb Core Composite Panel can be fully recycled, i.e. the panels are fed back into the material cycle and used in the production of new material. For 3A Composites GmbH, effective, continuous environmental protection is a main priority. It is of utmost importance to preserve natural resources in order to ensure a livable tomorrow for future generations. It commits itself to continuous self-improvement programmes for environmental protection, many of which go above and beyond government regulations. It is also in this area that 3A Composites GmbH strives to be a leader in its field. We were one of the first companies to develop our own environmental management system which is regularly audited by independent auditors. The certification according to EN ISO 14001 speaks for itself. -

STORAGE/ HANDLING

Make sure to protect HyGROW Aluminium Honeycomb Core Composite Panel against rain, any wetness penetrating the pallets and the formation of condensation. It is recommended to store a maximum of 6 pallets of identical size stacked on top of each other. Storage exceeding 6 months should be avoided, otherwise it could be difficult to remove the protective foils. When stacking the panels, nothing should be placed in between them, as this could produce marks on the panels.PROTECTIVE FOIL / CLEANING / MAINTENANCE

We recommend removing the protective foil as soon as possible after the installation. Due to UV radiation, it may occur that residual glue sticks to the surface of the panels. Do not mark the protective foils and panel surfaces with ink (markers), adhesive tape or labels. The solvents or softeners could damage the lacquered surface. Make sure to remove the protective foil as soon as possible after installation, as prolonged exposure to the elements could make the foil difficult to remove. The frequency of cleaning depends on the design and on the degree of soiling resulting therefrom. -

INSTALLATION

To avoid possible reflection differences (does not apply to solid colours), we recommend installing the panels in the same direction as marked on the protective peel-off foil. Colour variations may occur between panels originating from different production batches. To ensure colour consistency, the total requirement for a project should be placed in one order.WARRANTY

HyGROW Aluminium Honeycomb Core Composite Panel stands for high quality and longevity. Warranties according to the product specification and approved field of application can be obtained upon request.

Why Use Aluminum Honeycomb Panels?

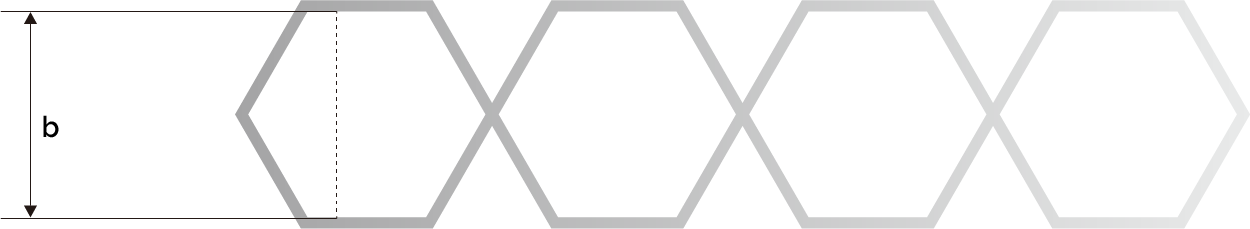

- 1. Aluminum honeycomb panels are a type of building material that is commonly used in the construction of aircraft, boats. and other structures. The panels are made from a sandwich of two aluminum sheets with a layer of honeycomb-shaped cells in between.

- 2. One of the key advantages of aluminum honeycomb panels is their strength and durability, The honeycomb structure of the panels provides an exceptionally high strength-to-weight ratio, making them ideal for use in applications where weight is a critica factor

- 3. In addition to their strength and durability. aluminum honeycomb panels are also known for their thermal and acoustic insulatior properties. The honeycomb structure of the panels is effective at trapping air, which helps to insulate the panels and reduce the transmission of heat and sound.

- 4. Aluminum honeycomb panels are a versatile and effective building material. Their strength, durability, and insulation propertie.make them an ideal choice for a wide range of applications.

When applications require a lightweight, high strength composite panel, aluminum honeycomb panels are often the best solution, The cell size, grade of aluminum, depth of the material, and thickness of the cell wall are all variables that can be specified to create a honeycomb panel with the best properties for your application.

As a general rule, these panels have the following attributes:

- Extremely Low Weight

- Excellent Strength

- High Resistance to Moisture

- High Resistance to Corrosion

- Excellent Thermal Conductivity

- Noncombustible

- High Resistance to Fungi